The current discussion about artificial intelligence (AI) and neural networks focuses primarily on generative applications (generating images, text, and videos), and it is easy to overlook real-world examples where AI will revolutionize industrial electronic components applications.

While the adoption of AI in real-time control systems for motor drives, solar and battery management applications won’t attract as much attention as new large language models, using edge AI for fault detection can significantly impact system efficiency, safety and productivity.

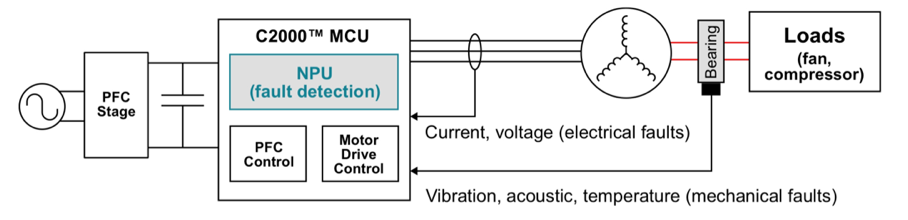

This article discusses how integrated microcontrollers (MCUs) can enhance fault detection in high-voltage real-time control systems. These MCUs use an integrated neural network processing unit (NPU) to run convolutional neural network (CNN) models, helping to reduce latency and power consumption when monitoring system faults. By integrating edge AI capabilities into the same MCU used to manage real-time control, you can help optimize your system design while enhancing overall performance.

Monitoring of Motor Bearings and Solar Arc Faults

Reliable operation of motor drives and solar systems requires fast and predictable system fault detection to help reduce false alarms, as well as monitoring of motor bearing anomalies and actual failures. Edge AI-enabled MCUs can detect two types of failures:

Motor bearing failure will occur when the motor bearings experience abnormal conditions or age. Detecting these faults is critical to preventing unexpected failures, reducing downtime and lowering maintenance costs.

A solar arc fault is an arc discharge that occurs when electricity travels through an unexpected path, such as air. Solar arc faults are often caused by insulation breakdown, loose connections, or other failures in the solar system. Discharge can generate intense heat, which can cause fire or damage to the electrical system. Monitoring and detecting solar arc faults helps prevent hazardous events and ensures the safety and reliability of solar systems.

Without responsive monitoring, systems can experience unplanned downtime or system failure due to actual failures or false alarms, impacting operational efficiency and operator safety. For example, a false alarm in a photovoltaic inverter can cause the system to shut down and require inspection, impacting productivity. Missed detection of live arcs also increases the risk of fire or system damage.

In addition to MCUs, some motor bearing failure monitoring methods use multiple devices to achieve real-time control, monitoring through vibration analysis, temperature monitoring, and acoustic measurements. This discretization approach then uses data-based rule detection to monitor potential failures, which requires manual parsing and may miss early failures or fail to accurately detect failure types.

Likewise, the traditional approach to arc fault detection is to analyze the current signal in the frequency domain and then apply threshold-based rules to detect the arc fault signal. But both methods require a lot of system expertise and are limited in adaptability and sensitivity, thus limiting detection accuracy. Additionally, adding discrete devices for fault monitoring and dedicated real-time control MCUs for motor control increases system complexity.

Integrated fault detection based on edge AI runs CNN models natively in real-time MCUs such as the TMS320F28P550SJ, helping to increase fault detection rates, avoid false alarms, and provide better predictive maintenance. With edge AI, these systems can learn and adapt to their environment to optimize real-time control, improve overall system reliability, safety, and efficiency while reducing downtime (see figure ).

How to Enhance CNN Model

Fault monitoring and detection in real-time control systems

CNN models for motor bearing and arc fault detection can learn complex patterns from raw sensor data, such as vibration signals, and then detect subtle changes that indicate bearing failure.

Because CNN models can autonomously learn from raw or preprocessed sensor data (such as motor vibration signals, solar DC current, or battery voltage and current), CNN models are well suited for sensor data analysis for fault detection and predictive maintenance. Meaningful features can be extracted directly without manual intervention, resulting in robust and accurate detection. At the same time, sensor data representing variable operating conditions and different hardware changes, as well as different preprocessing algorithms such as Fast Fourier Transform (FFT), can be utilized to improve the adaptability, noise immunity, and reliability of the model while reducing the total detection or Reasoning delays.

Since CNNs can efficiently process large amounts of data and perform well under different operating conditions, they are suitable for real-time monitoring and predictive maintenance in industrial environments. Employing CNN models in these environments can enable earlier and more effective detection of motor bearing failures, thereby improving equipment reliability and operating efficiency.

For motor drives, CNNs can identify failure modes such as bearing wear or rotor imbalance caused by vibration or current signals. In solar systems, CNNs can detect anomalies in DC current waveforms for arc fault detection. In battery management applications, CNN models can analyze battery charging curve life, perform battery health monitoring and battery state-of-charge estimation. The CNN's adaptability ensures accurate fault detection under dynamic conditions, and real-time processing improves efficiency.

————————

About Perceptive Components Limited

We are one of the world's leading distributors of semiconductor and electronic components. With 21 years of business experience in the electronic components industry, we have in-depth cooperative relations with thousands of brand manufacturers and agents, focusing on TI, Microchip, NXP, Infineon, Intel, onsemi, ST, Micron.

To learn more about Perceptive, visit other electronic parts product categories on our official website.